AdvUSMachining

About the Project The AdvUSMachining project aims to develop and implement an innovative prototype for an ultrasound-assisted cutting tool. This technology is designed to be attachable to conventional machining equipment (machining centers) using standard taper fitting systems, facilitating its integration into the industry.

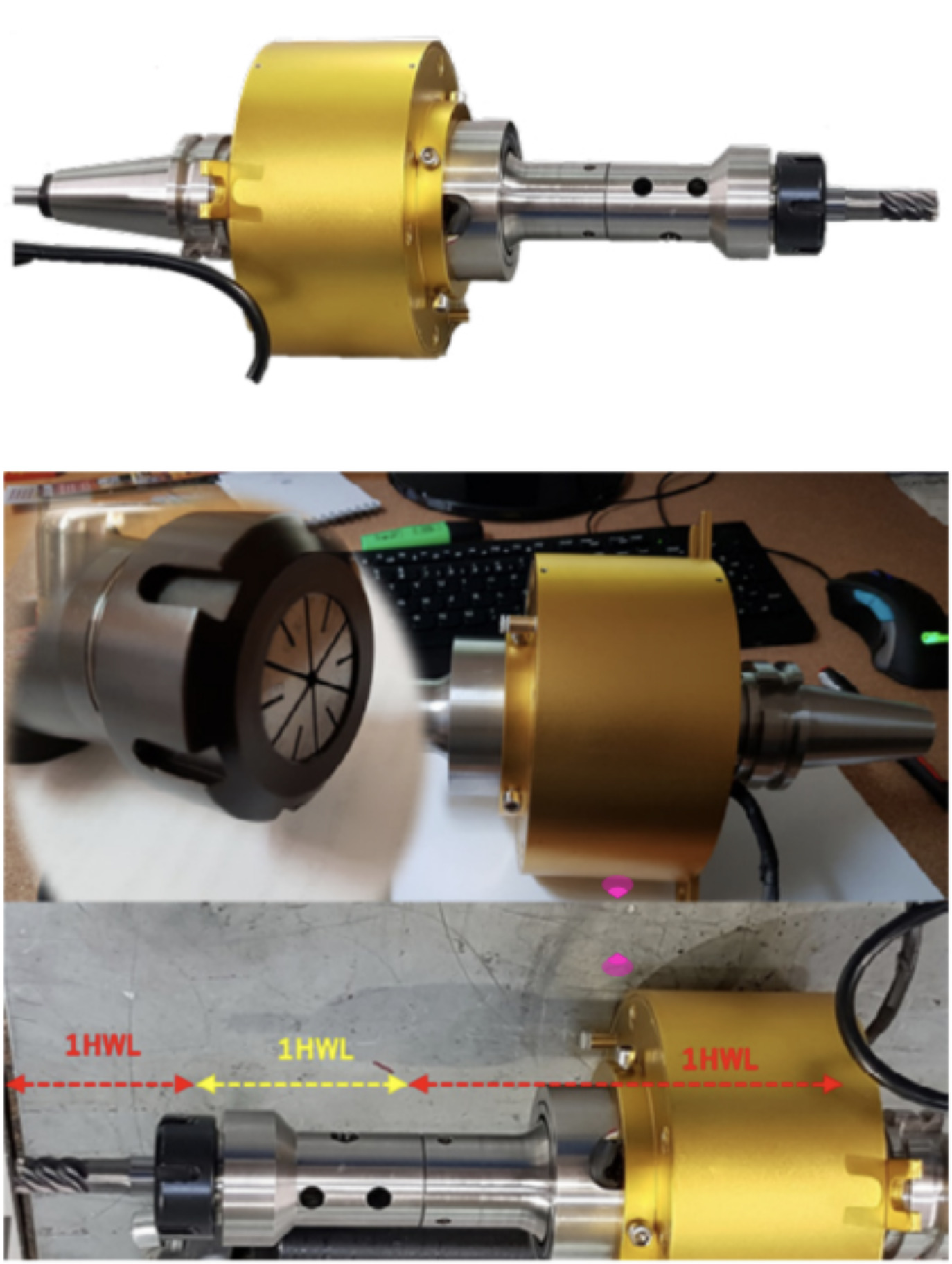

How It Works The technology is based on applying acoustic excitation (ultrasound) to the cutting tool. This generates an axial resonance movement which, combined with the conventional rotary motion, creates intermittent contact between the tool and the workpiece. The system uses an ultrasonic generator with MMM (Multifrequency, Multimode, Modulated) technology to dynamically adjust the frequency and maintain maximum cutting efficiency.

Competitive Advantages Introducing ultrasound-assisted vibration overcomes the limitations of traditional processes, offering:

- Improved Quality: Superior surface and geometric finish.

- Thermal Efficiency: Reduced operating temperatures, decreasing the need for cutting fluids or allowing for higher cutting speeds.

- Cutting Capacity: Reduced cutting forces, enabling the machining of high-hardness materials.

- Productivity: Reduced production times through increased feed rates and depths of cut.

Impact and Application This solution is intended to boost competitiveness in high-value-added sectors such as the automotive, aeronautics, and mold industries. The project empowers companies to work with technologically advanced materials that are difficult to process with traditional technologies, promoting "Technology-Pushed Product Innovation".