CuTOS

Several methods aim to transfer acoustic energy into a bath of molten metal; however, none of these methods is affordable and susceptible to be applied in industrial casting because there is no acoustic radiator material available to support high temperatures without suffering erosion. Furthermore, the acoustic transmission range has limitations due to the attenuation effect caused by the viscosity of the molten metal, further the cavitation effect.

The present disclosure relates to an ultrasonic-assisted ladle for transfer of the alloy applied to non-ferrous alloys’ melt treatment and method thereof.

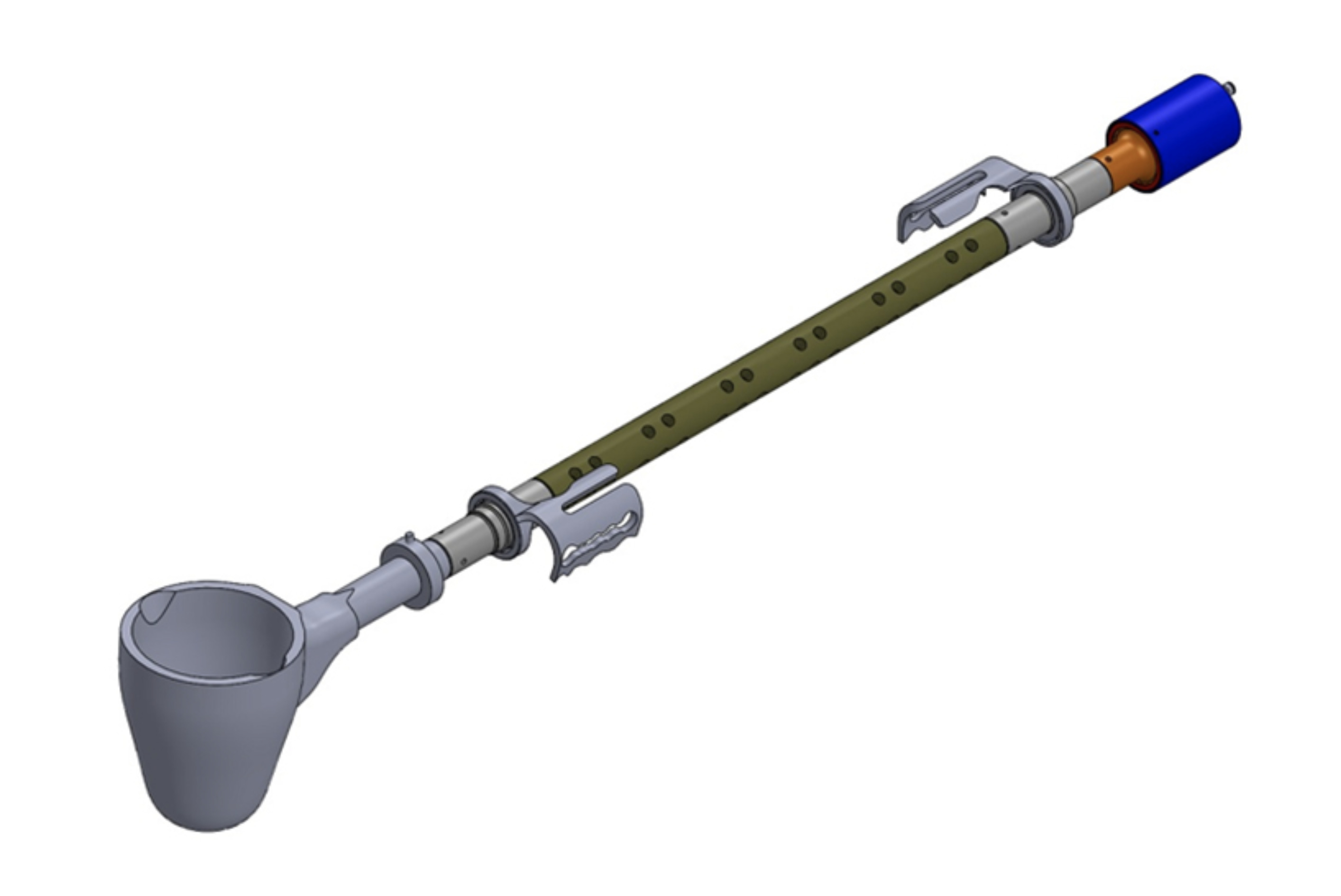

It is disclosed a ladle using ultrasonic vibration when transferring alloy melt from a crucible to a mould, the steps of melt degassing, microstructure refining, and addition of micro/nanoparticles. A transducer produces the ultrasonic vibration, preferably a piezoelectric transducer, which is transferred through a booster and a waveguide properly designed and directly applied to the ladle, which contains the liquid metal, creating cavitation bubbles. In another embodiment, an inert purge gas is intentionally supplied through a channel designed adequately in the waveguide, enhancing the cavitation bubbles number involving the entire molten metal volume. The combined effects result in a fast step of degassing and refinement, directly applicable in the gravity casting process.

The ultrasonic-assisted ladle for transfer of the alloy applied to non-ferrous alloys’ melt treatment can result in metals purification; microstructure refinement; structure modification providing a better and faster melt homogenization, optimized alloying and microalloying, wetting of non-metallic inclusions and significant alloy density increase; and degassing, based on the specifically created acoustic field introduced in molten metal in order to create spatially and uniformly well distributed and wideband multi-frequency cavitation.

The present disclosure relates to a novel, reliable and feasible apparatus and method to transfer the molten metal alloy from a crucible or furnace to a mould cavity using a ladle assisted by ultrasound. In an embodiment, the device transfers the molten metal from a holding furnace which is a small furnace for holding molten metal produced in a larger melting furnace at a desired temperature for casting. One of its objectives is to provide a simple and affordable way for foundrymen to proceed with the treatment during pouring, combining degassing and matrix refinement in a single step, which can be applied directly to the conventional Foundry and casting without implying any additional expenses.